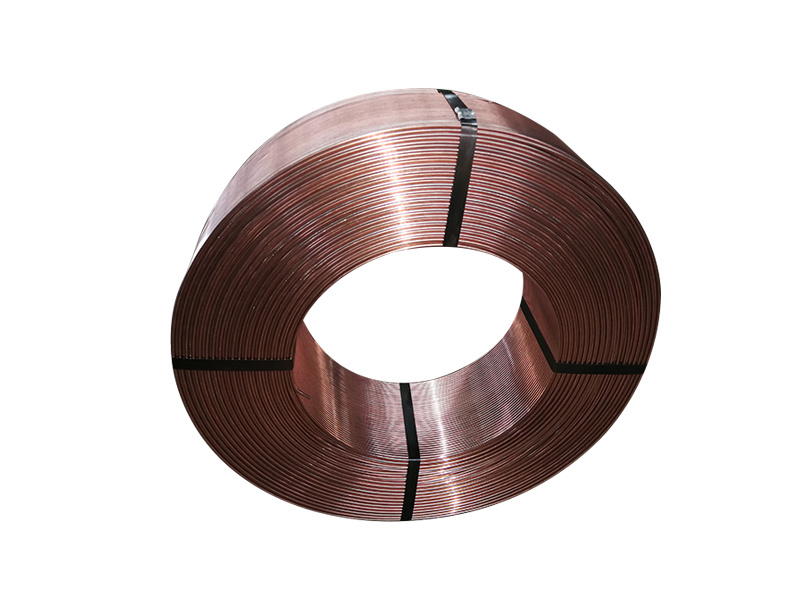

Flux cored wire

Our company mainly produces products: all kinds of carbon steel gas welding wire, carbon steel submerged arc welding wire, aluminum alloy gas welding wire, aluminum argon arc welding wire, stainless steel gas welding wire, stainless steel submerged arc welding wire, alloy steel wire, flux cored wire, All kinds of welding accessories, such as the top ten series of hundreds of varieties.

Category:

Flux cored wire

Hotline:

product details

As early as the early 1950s, gas shielded flux cored wire was developed and marketed, but it was not widely used commercially until 1957. This method can be said to be a combination of the advantages of submerged arc welding and CO2 welding (solid). The welding flux is wrapped in the welding wire and protected by the surrounding CO2 gas, so that a softer and more stable arc and low spatter can be generated during welding. At the beginning of development, only large diameter welding wire (2.0-4.0mm) was used for flat welding and transverse welding of major workpieces. It was not until 1972 that the small wire diameter welding wire began to develop that the application field of flux cored welding wire was greatly expanded.

Self shielded flux cored wire was developed in the market of gas shielded flux cored wire soon and was widely recognized by the industry for specific purposes.

The biggest difference between the two has been described in the second unit. This unit only discusses the whole.

It is also reported that the proportion of welding rods in Japan has decreased from 45% to 20% since 1985; The proportion of flux cored wire has reached nearly 30%. In the United States, the proportion of welding rods has dropped to less than 40%, while that of flux cored wires is close to 40%; The welding rods and flux cored wires in Western European countries account for about 30% and 20% respectively. It can be seen that flux cored wire has obvious advantages compared with manual electrode and argon arc welding wire. It mainly changes intermittent welding process into continuous production mode, thus reducing the number of welding joints, improving the weld quality, improving production efficiency and saving energy.

Pre

Next

Pre

none

Next

Recommended products

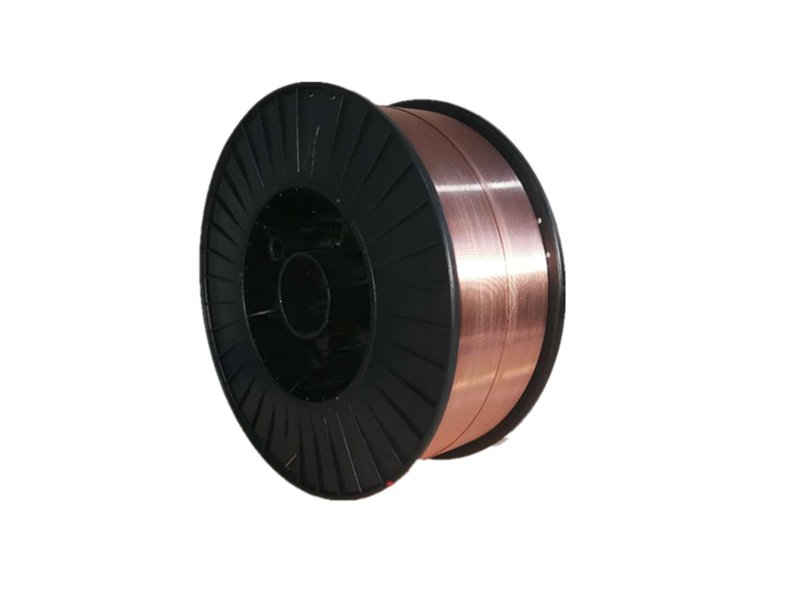

Gas shielded welding wire

The welding wire is used as a filler metal or as a metal wire welding material for conducting electricity at the same time.

Gas shielded welding wire

The welding wire is used as a filler metal or as a metal wire welding material for conducting electricity at the same time.

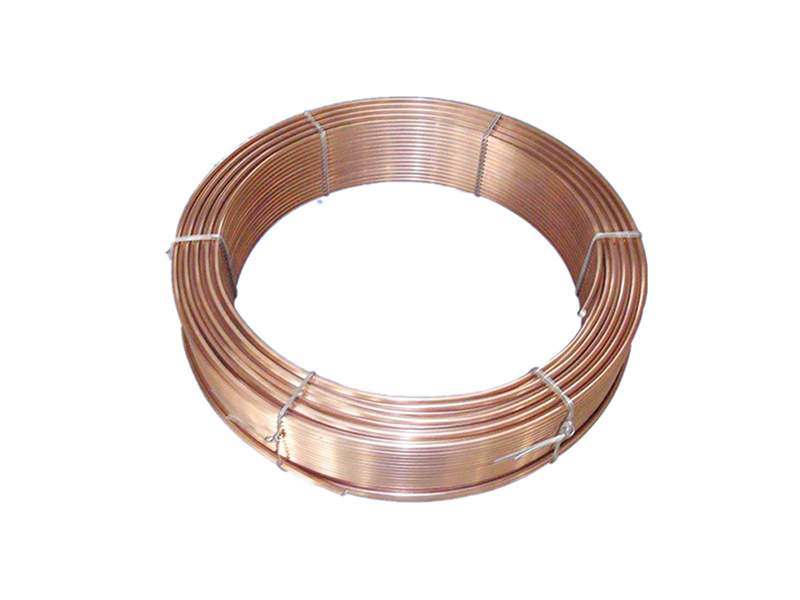

Submerged arc welding wire

Submerged arc welding wire is one of the welding materials, which is used for welding carbon steel and alloy steel with lower strength.

Submerged arc welding wire

Submerged arc welding wire is one of the welding materials, which is used for welding carbon steel and alloy steel with lower strength.

Provide you with solutions and prepare for your choices